DDC-125 Drawdown compressor

portable emissions recovery

PPI Gas Distribution Inc. proudly supplies the DDC-125 Gas Drawdown Compressor, ensuring gas distribution utilities have access to cutting-edge emissions recovery technology. As a trusted distributor, PPI Gas works with ULC Technologies to provide guidance and ongoing support for customers integrating the DDC-125 Gas Main Drawdown Compressor into their operations. With a commitment to innovation and methane mitigation, PPI Gas helps utilities transition to cleaner, more efficient gas distribution practices. Our solutions support closed-vent systems and the safe handling of pipeline gas, making them ideal for gas utility construction projects and the maintenance of natural gas pipelines in the U.S.

The full Drawdown Compressor Unit.

The full unit at a job site.

The full unit at a job site.

The full unit at a job site.

The full unit at a job site.

Connection to main.

Eliminate Emissions During Gas Distribution Operations

The DDC-125 Drawdown Compressor is a patent-pending solution designed to recover stranded natural gas during maintenance and construction activities. By compressing and reinjecting gas into the active system, it eliminates the need for venting or flaring, significantly reducing emissions. With a natural gas-powered engine, automated safety features, and industry-leading speed, the DDC-125 is the ideal choice for modern gas distribution networks.

Want to learn more about the DDC-125 Drawdown Compressor? Contact us to schedule a demo or to learn more about this game changing product.

ULC Drawdown Compressor Safety

Annunciator panel control engine and has automated safety shut-offs built in. Monitors include:

Safety blow-offs on the intake and discharge manifolds to prevent unit from over pressurizing.

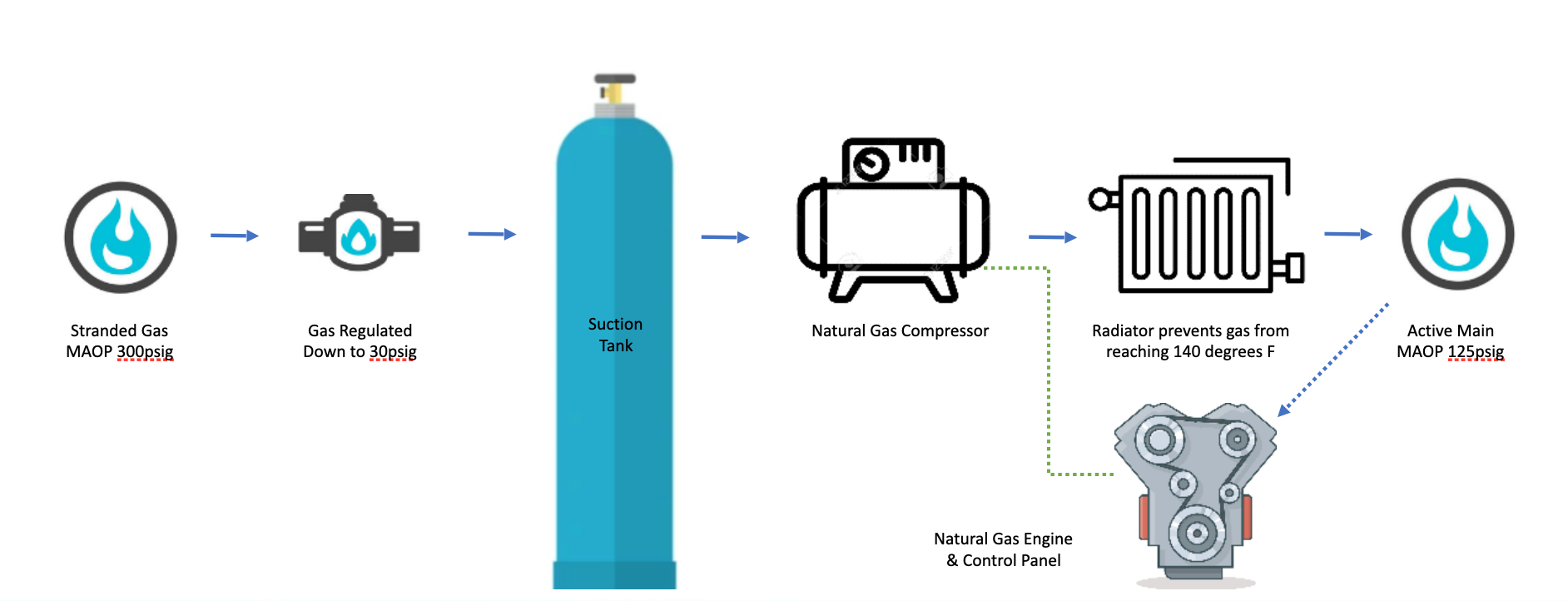

Radiator engages when natural gas reaches temperatures above 100 degrees F to ensure gas stays below 140 degrees F. At 140 degrees F, unit will automatically shut down.

ULC Drawdown times are 4-5x faster

ULC Drawdown Time Versus Competitor A Drawdown Time

| Pipe Length and Pressure | ULC DDC-125 | Competitor A, Product 1 | Competitor A, Product 2 |

|---|---|---|---|

| 5280 ft of 8", 25psig | 18 min | 3 hours | 2 hours |

| 5280 ft of 8", 100psig | 25 min | 7 hours | 4 hours |

ULC Drawdown Time Versus Competitor b Drawdown Time

| Pipe Length and Pressure | ULC DDC-125 | Competitor B |

|---|---|---|

| 2000 ft of 8", 110psig | 11 min | 1 hour |

| 2000 ft of 16", 110psig | 37 min | 4 hr 15 min |

| 2000 ft of 8", 60psig | 10 min | 40 min |

| 2000 ft of 16", 60psig | 32 min | 2 hr 35 min |

Drawdown compressor process

What is the ULC Drawdown Compressor?

The ULC Drawdown Compressor is an innovative solution that captures natural gas from isolated pipeline sections and reinjects it into the active network using cross compression. It’s designed to help utilities meet government regulations and reduce emissions.

What are the key specifications of the DDC-125 unit?

The DDC-125 features a maximum inlet pressure of 300 psi, a maximum outlet pressure of 125 psi, and an average flow rate of 150 cfm. It operates without an external compressor by utilizing natural gas from its discharge, with propane available as an alternate fuel source.

What safety features are included in this unit?

Safety is built into every aspect of the design. An annunciator panel monitors various parameters—such as suction and discharge pressures, engine and compressor oil levels, and temperatures. Additionally, safety blow-offs prevent over-pressurization and a radiator system ensures the gas stays below 140°F by automatically shutting the unit down if needed.

How does the compressor improve efficiency and reduce environmental impact?

By capturing gas that would otherwise be vented during maintenance or abandonment projects, the compressor reinjects the recovered gas back into the pipeline. This not only boosts operational efficiency but also helps utilities reduce their environmental footprint.

How is the unit connected to the main pipeline system?

The compressor integrates seamlessly via a “tree” system that connects the drawdown hoses to the main. It requires a 2” female NPT connection, with a preferred tap size of 2” (minimum 1”), and includes built-in gauge points and pressure relief for reliable operation.

Why Choose PPI Gas Distribution?

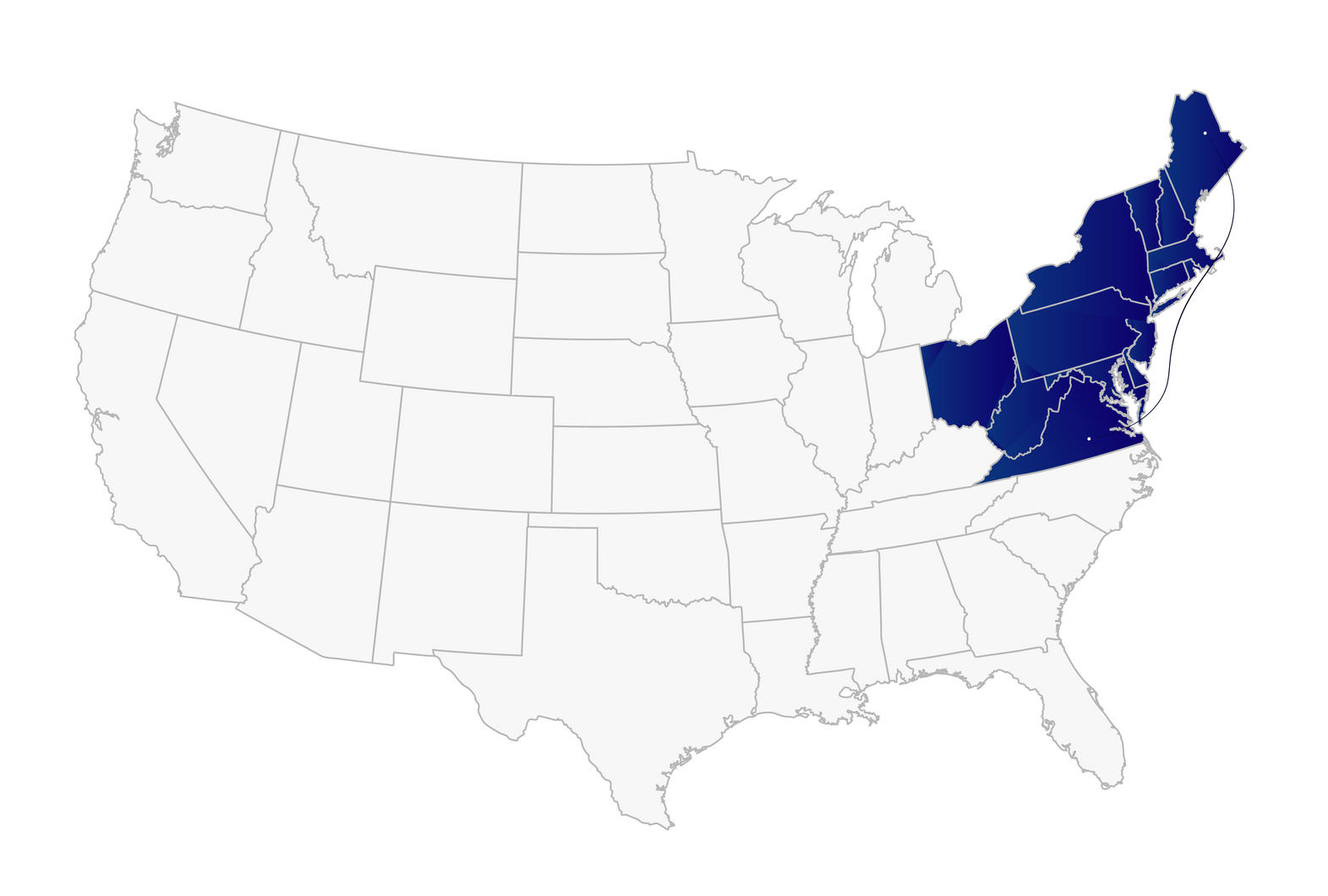

SERVING CLIENTS FROM MAINE TO VIRGINIA SINCE 1997

At PPI Gas, we are proud to work with a number of licensed and certified gas fitting manufacturers across the United States. We pride ourselves on providing exceptional customer service, building relationships with clients where we know each other on a first name basis. To learn more about us, you can visit our about page and watch our introduction video!

Serving Gas Clients Since 1997

Major Distributor in the Northeast

Hassle-Free Repairs Available